The x,y, and z axes are complete.

Pictured sideways on the bench while I aligned the y axis rails.

Y and z limit and home switches ar also installed

Sunday, December 13, 2009

Mechanics near complete...

Thursday, December 25, 2008

Extruder Design

After successful lashups, I've completed design for a "prototype" version. I have the materials, just need to construct.

In addition to minor fixes from the lashup, the main difference is use of an aluminum housing instead of the cement board. The hope is that the housing will dissipate the heat by operating as a large heatsink.

This extruder design aims to work towards eliminating the PTFE part. This version still uses the PTFE, but not as a structural element. Later, I hope to cool the inlet and avoid the PTFE.

Sunday, September 28, 2008

SVG SLices to avoid STL

An initial ( and promising ) version of my SolidWorks slicing macro is complete--

the macro slices the part and creates loops ( hopefully that coudld be imported into skeinforge directly), avoiding STL-hole hell.

Here was the test part:

The SVG that was created is machine-friendly, and is here:

TestPart.svg

(You will need Firefox, Opera, or an SVG viewer to view the file )

The SVG links in a sytlesheet and some javascript to render a layer paging control.

SVG is smart enough to understand how to fill loops, so it works quite nicely as a display format as well as a way to communicate path information.

Unfortunately after trying my scripts out on a couple of other parts, I found that there is a bug in Solidworks that has problems cutting solids through circular faces, which is very disappointing. I am working through that now.

In the meantime, perhaps this is a good start for folks interested to use for their efforts...

My code is released under a "do whatever you want with it" license-- enjoy!

Saturday, August 23, 2008

Filament Guide Rollers

I had noted that nophead and others were lubricating the filament to keep friction down on the filament during feeding, and for my design wanted to come up with a better way.

These rollers are skate bearings with an aluminum ring pressed around them. The rings only took a few minutes to make from a piece of aluminum tubing on the lathe.

The rollers are mounted on a small stud of drill rod with an eccentric hole, so that they are adjustable by twisting the mounting stud and tightening the screw.

I tried designs that had 3 rollers and that had only 1. Based on some basic calculations, i'd computed that i'd need about 6-8 threads to engage to make ensure that the filament would buckle coming out before the threads would strip the ABS, so I was unlikley that 1 roller would work. That turned out to be the case-- 1 roller does not force enough thread contact to feed under worst case conditions. 3 was overkill, so 2 is what i ended up with.

This version is just a lashup, the rollers are too far from the exit at this point, but still the concept works very well.

I believe that the adapter rings could be rep-rapped also, and perhaps a semi circular profile could be used in that case. I did a v-groove because I could use a 90 degree lathe tool i already had and didnt want to grind a semi-circular profile tool...

Extruder Lashup

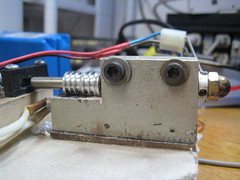

The holding block has a hole for the catridget heater, and holds the barrel via a clamping arrangement with the bolts at the top.

I wanted to operate at temperatures above what PTFE could handle, so I used a three-part extruder barrel:

The lower barel is brass, threaded on both ends to accept the acorn nozzle and the adapter.

The adapter is aluminum, with fins cut into it to maximize cooling

The entry end is stainless steel, and threads into the adapter.

The result is that the heat gradient over the entire barrel is enough to keep the entry point cool, while the brass part melts the plastic.

Friday, August 22, 2008

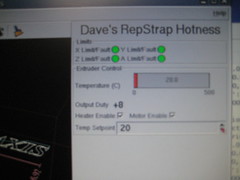

Extruder Control works..

there's a pretty simple python hal user space driver installed communicating on the serial port, and a pyVCP plugin reading the temperature. I can also disable enable and set the temperature manually until i get the M-apps working.

One bonus goodie is that the board also has an IO pin ( parallel port ) for fault output-- if the extruder is not enabled, EMC will see a limit error and the lights that are green will be red...